Macmillan Pass or Tom-Jason Project in Yukon Territory, Canada, hosts large zinc, lead, and silver deposits. According to the January 2018 Mineral Resource Estimate, Macmillan Pass is one of the most significant zinc resources in the world.

Canadian mining exploration and development company Fireweed Metals has 100% stake in the property.

According to an independent Preliminary Economic Assessment (PEA) announced in 2018, the proposed site is expected to mine 32.66 million tonnes (Mt) at a diluted head grade of 9.07% zinc equivalent (5.31% zinc, 3.56% lead and 43.41g.t silver) with an average processing rate of 4,900 tonnes per day (tpd) over 18 years.

The 2022 drill programme at the property has been completed with assay results being interpreted.

Project Gallery

-

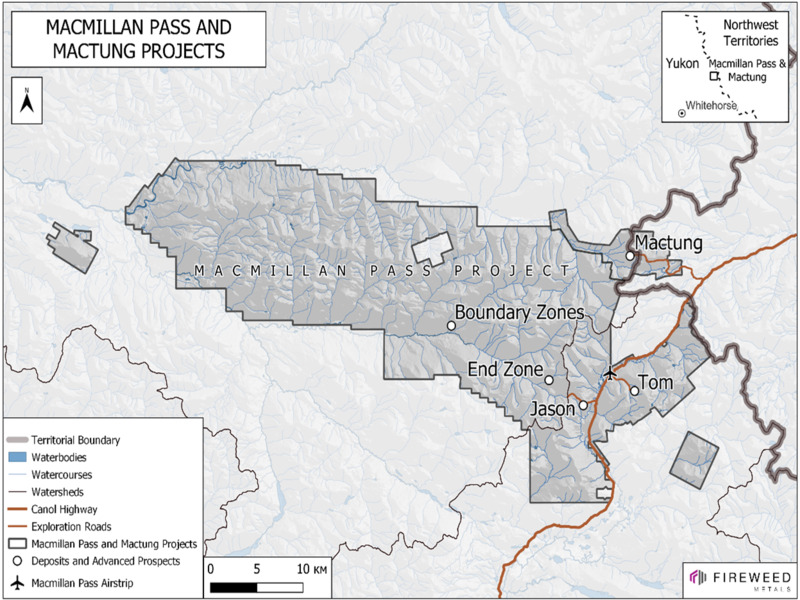

The location map of the Macmillan Pass Project. (Credit: Fireweed Metals Corp.)

-

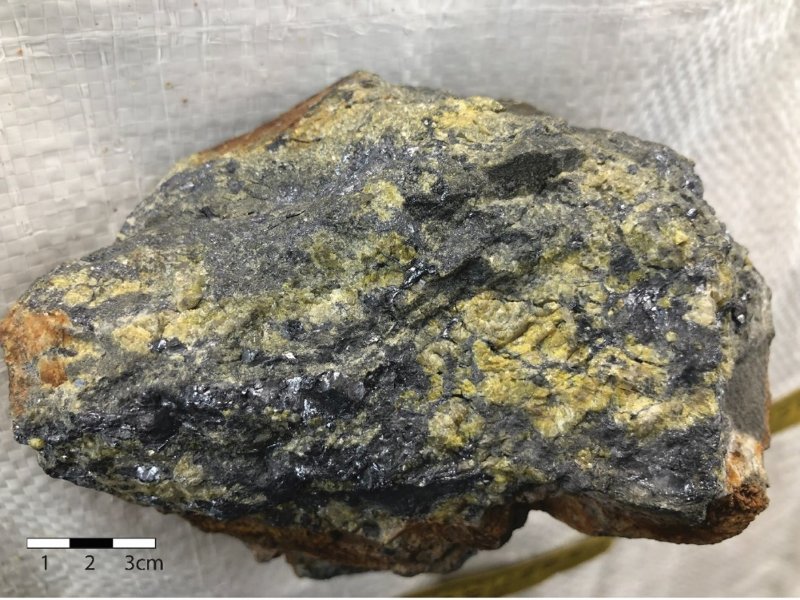

Massive galena with abundant light-green crystalline sphalerite within Lower Host unit of the property. (Credit: Fireweed Metals Corp.)

-

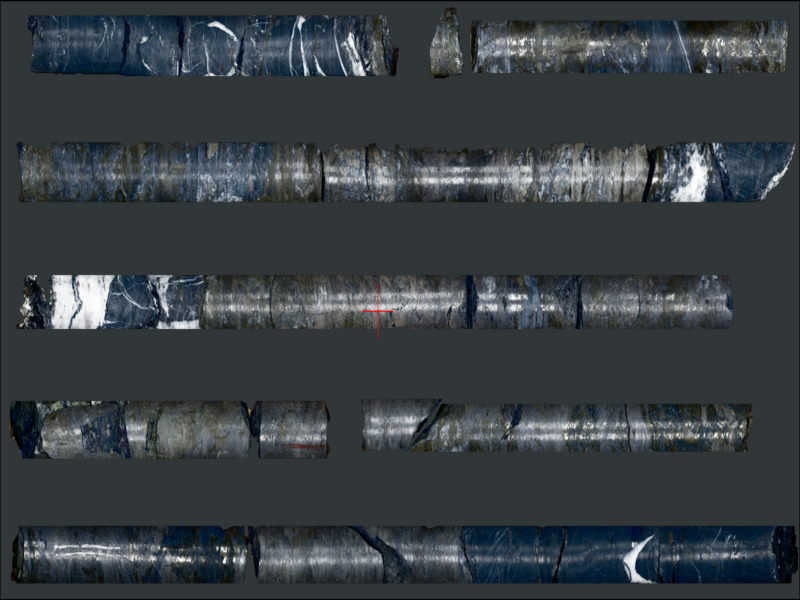

The Scanned image of the sulphide core from NB22-002. (Credit: Fireweed Metals Corp.)

Location and Site details

The 940km2 Macmillan Pass Project land package is located in eastern Yukon Territory of Canada.

The project is situated near the border with the Northwest Territories, approximately 400km northeast of the Whitehorse City.

It features multiple contiguous blocks of claims including Fireweed-owned Tom mining lease and the Jason claims. Fireweed has the MAC, MC, MP, Jerry, BR and NS claim blocks under option from third parties. Overall, it includes a total of 2,528 claims covering about 469km2.

The site can be accessed by air or seasonal gravel road.

Ownership history

The Tom Property has been owned by Hudbay through various subsidiaries since its discovery and staking in 1951. Between 1988 and 1992, it was temporarily optioned to Cominco.

The Jason Property was first staked in 1971 by Ogilvie Joint Venture. The ownership of the property was passed to Hudbay in 2007.

In December 2016, Hudbay signed a Definitive Option Agreement for the Tom and Jason Properties Fireweed, which exercised the option to acquire full ownership in the Tom and Jason Properties in February 2018.

The MAC Property; MC, MP and Jerry Claims; BR and NS Claims are under option agreements.

Geology and Mineralisation

The Tom and Jason are proximal, stratiform, sediment-hosted (SEDEX) deposits that formed during Devonian era rifting activity in the Selwyn Basin.

The Tom Deposit is hosted by the Portrait Lake Formation of the Devonian Earn Group, while the Jason Deposit is hosted by a Devonian sequence disrupted by the Hess Fault and folded into a series of ‘upright tight west trending and shallowly east plunging folds’.

The Selwyn Basin is one of the most prolific basins for SEDEX zinc-lead-silver deposits in the world. It hosts 12 large deposits including the Tom and Jason deposits.

Mineralisation occurs at or close to the seawater-sediment interface either proximal or distal to syn-sedimentary faults.

The more distal deposits are largely stratiform, while proximal deposits are more linked spatially with syn-sedimentary feeder faults and exhibit more complex metal zonation and replacement textures.

The metal ratios, such as Ag/Pb, Pb/(Pb+Zn), Cu/((Zn+Pb), Zn/Fe and Zn/Ba are found increasingly towards the feeder faults and vents.

Mineral Resource Estimate

In the indicated category, the Tom and Jason deposits have a combined resource of 11.21 Mt @ 9.61% zinc equivalent (ZnEq) containing 1.63blbs of zinc, 0.61blbs of lead and 7.69moz of silver.

The figure stands at 39.47Mt @ 10.00% ZnEq in the inferred category.

Mining and Ore Processing

Fireweed plans to employ a range of mining methods to extract mineral resources from the property.

This will include Open Pit Mining (OPM), Long Hole Stoping (LHS), Vertical Crater Retreat (VCR), Sub-Level Retreat (SLR), Alimak Stoping (ALS), and Development and Cross Cuts (XCO).

Initially, the mineral deposits will be mined by open pit methods. The underground operation will be ramped up to maintain a nominal throughput of 5,000tpd to the mill after open pit resources are depleted.

There will be two crushing plants- one underground for Tom and one near the crushed material stockpile for Jason, and a process plant to produce saleable Pb and Zn concentrates.

The process plant will use a semi-autogenous grinding (SAG) mill / ball mill grinding circuit to achieve a P80 grind size of 50µm, before the material is passed to Pb and Zn rougher/cleaner flotation circuits. The Pb and Zn regrind circuits will be designed to produce P80 grind sizes of 15µm and 25µm respectively.

Infrastructure

The infrastructure of the project will include upgradation of 230km of the Canol Road to an all-seasonal access road from the Ross River to the project’s site.

The project will also involve construction of process facilities, natural gas power plant and liquefied natural gas (LNG) receiving and storage facility, Tailings Management Facility (TMF) and Waste Rock Storage Facilities (WRSF), permanent camp for construction phase, truck shop, warehouse, mine dry, office complex, and 300,000lt of on-site fuel storage and distribution among others.

It will also have an airstrip extension, industrial waste management facilities such as incinerator, site sewage treatment facilities, site storm water management facilities, and telecommunication facilities.

Power Infrastructure

On-site generator sets will be used to supply power for project’s operations.

A power plant comprising eight natural gas-fired reciprocating engine generator sets (gensets) in a N+2 (6+2) arrangement will be developed. This plant will supply electricity to the mine, processing plant, and other facilities.

For efficiency in operations, the power plant will operate as a Combined Heat and Power Plant (CHP). The LNG storage facility will supply fuel to the plant for operations.

Contractors involved

JDS Energy and Mining prepared the Preliminary Economic Assessment (PEA) for the Macmillan Pass Project.

The scope of work included PEA management, NI 43-101 report writing, underground and open pit mine geotechnical analysis, mine design and planning, metallurgical test programme management, process plant design, infrastructure design and mining, processing and infrastructure CAPEX and OPEX estimation.

As a subcontractor, CSA Global Geosciences Canada assisted JDS with property description, geology and mineral resources. Knight Piésold helped JDS with mine closure, mine waste and water management.

The metallurgical testing programmes for the project in 2012 were performed by G&T Metallurgical Services. The test works focused solely on Tom Deposit.

For 2022 core scanning programme, Fireweed Metals contracted GeologicAI. Additionally, Ideon Technologies was selected for 2022 muon tomography survey programme.