The Clearwater Lithium Project is a proposed mining operation in Southern Alberta, Canada. The project is expected to involve pumping lithium-enriched saline water from wells to a Central Process Facility, where the lithium will be extracted and purified.

E3 Lithium, previously known as E3 Metals, is the owner of the property.

A Preliminary Economic Assessment (PEA) of Clearwater Lithium Project was reported in December 2020.

The development plan prepared for the PEA is designed to deliver 20,000 tonnes per year of battery-quality lithium hydroxide monohydrate (LHM) over a 20-year period.

Project Gallery

-

The Clearwater Lithium Project is located in Alberta, Canada (Credit: Calistemon at commons.wikimedia.org)

-

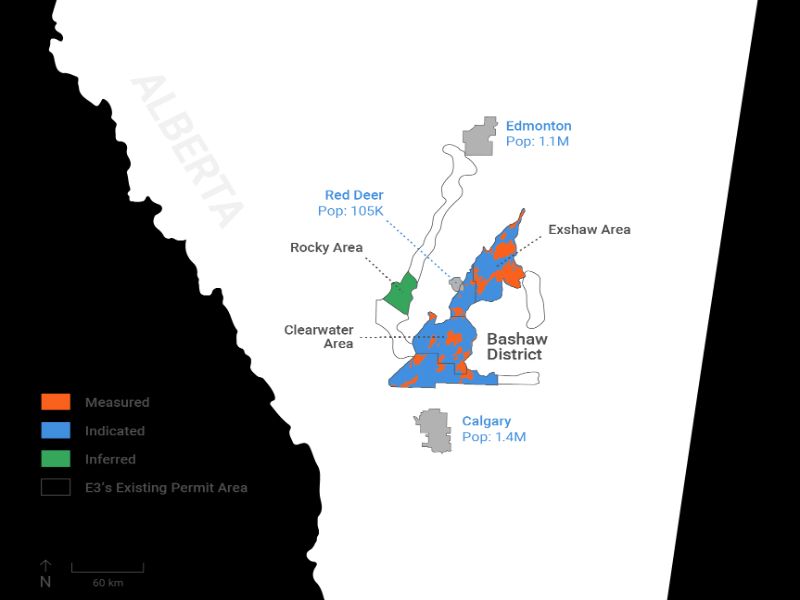

Map of E3 Lithium’s Measured, Indicated and Inferred Resources. (Credit: E3 Lithium)

-

A Preliminary Economic Assessment (PEA) of Clearwater Lithium Project was reported in December 2020. (Credit: Tim Evanson/ Flickr)

The total initial capital cost of the project is estimated to be $602m, including direct and indirect costs and contingency. The project secured C$27m in federal funding in November 2022.

Clearwater Location and Site Details

Clearwater is a sub-project area of the Alberta Lithium Project which consists of 80 metallic and industrial mineral permits overlying the Leduc Aquifer in Southern Alberta.

Apart from Clearwater, the 600,333-hectare property comprises five other sub-project areas. They are Rocky, Exshaw, Drumheller, Sunbreaker, and Meadowbrook-Rimbey.

The Clearwater area consists of 21 Metallic and Industrial Mineral (MIM) Permits covering an area of 157,305 hectares.

Of these permits, 13 lie completely or partially intersect the Central Clearwater Resource Area (CCRA) boundary with 50,464 hectares falling within the boundary.

History of the Clearwater Lithium Project

No drilling programmes were conducted in the permit area to target lithium enriched brine. The existing wells were drilled for petroleum and natural gas.

The oil and gas operators did historical testing of lithium in water before E3 Metals, as part of routine chemistry analysis.

The data from testing were compiled in a comprehensive overview of the mineral potential of formation waters by the Government of Alberta.

Subsequently, AGS collected brine in water from actively producing oil and gas wells to analyse for lithium.

Geology, Mineralisation and Mineral resource estimate

The Clearwater project’s area includes a portion of the Wimborne-Bashaw complex to the east of the Meadowbrook Rimbey trend.

The Leduc build-ups are encased and overlain by the basinal shales and carbonate muds of the Duvernay and Ireton, thus creating traps for hydrocarbon pools.

These shales also form aquitard for the Leduc and Cooking Lake aquifer systems, which contain lithium-enriched brine associated with reefal carbonates of the Woodbend and Winterburn Group.

In E3 Lithium’s properties, the lithium accumulations occur mainly within brines contained in dolomitized reefs of Devonian Leduc age.

A secondary accumulation occurs at a higher elevation in the biostromal development in the Nisku Formation of the Devonian Winterburn Group.

According to PEA, the Central Clearwater Resource Area inferred mineral resource estimate is 5.5 billion m3 of brine at 74.6mg/L, totalling 2.2 million tonnes of LCE using conversion factor from elemental lithium of 5.323.

Mining and Processing

For the PEA of the Clearwater Lithium Project, lithium enriched brine is sourced from the deep vertical or deviated wells into the Leduc aquifer.

The brine will be transported to the Central Processing Facility (CPF) via underground pipelines to extract lithium. Lithium void brine is then transferred back to the Leduc aquifer through deep vertical or deviated injection wells.

No surface mining methods were utilised for this project.

Direct lithium extraction methods developed by the company are used to extract and recover lithium.

After H2S removal during pre-treatment, lithium in brine is concentrated by ion exchange sorbent material in a counter-current sorbent-in-pulp style system. The sorbent mainly absorbs lithium from brine eliminating bulk of impurities.

Subsequently, majority of the remaining species such as calcium, magnesium, manganese, boron, and strontium are removed as hydroxides and carbonates by precipitation.

At this stage, the Li+ stream is very dilute and to prevent membrane fouling, the lithium enriched eluate undergoes Reverse Osmosis (RO) for further concentration.

The remaining divalent ions, Ca+ and Mg2+ are removed in secondary ion exchange circuit.

The purified brine, containing Li+, K+, and Na+ cations, undergoes electrolysis and crystallisation, resulting in LiOH.H2O.

Clearwater Project Infrastructure

E3 Lithium plans to develop five surface well pads for brine production, including 21 wells each at two well pads in the north and two additional well pads in the south.

Brine from the well pads will be pumped via individual wellhead Electric Submersible Pumps (ESPs) through a fibreglass pipeline to the Central Processing Facility (CPF)

The infrastructure includes well pads for brine production, production pipelines, a central processing facility, and natural gas supply for power generation.

The central processing facility houses brine treatment facility, two rows of injection well pads, and injection pipelines.

The Clearwater Lithium Project requires approximately 99MW of power for operations.

Although the primary power supply at the CPF will be utility power, a single gas fired power generation unit will be installed as backup.

Contractors involved

Fluid Domains, Scovan Engineering, NORAM Engineering, and GLJ supported the preparation of the Preliminary Economic Assessment for Clearwater Lithium Project, effective December 2020.